Services

Mist eliminators

PROCESS EQUIPMENT DESIGN:

Process Design provides the necessary data to select proper tower internals for separation, & mixing application. It is require for understating of the purpose of separation or mixing.

It is essential to know the feed composition and required temperature&pressure of the process. GDT also provides designs for our all products & as per our clients requirements. We have excellent team for design of static mixer, column internals, Distillation column, reactors &agitators, mist eliminators, etc, for efficient result & purity of product.

Mist eliminators :

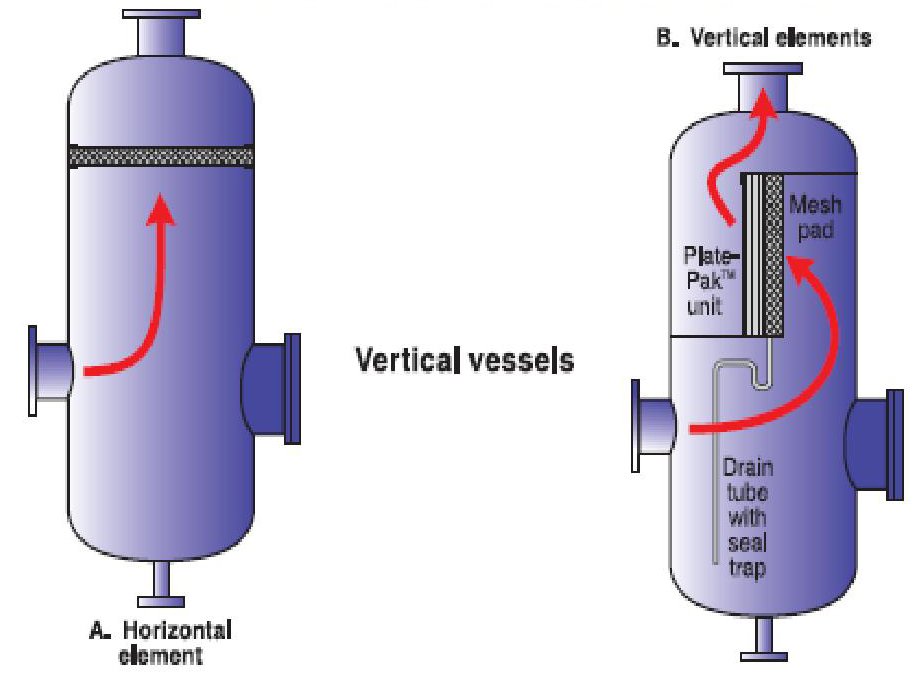

GDT offers both wire mesh and vane type mist eliminators. Mist eliminators are employed at the top of a packed column or in conjunction with a collecting tray between two packed beds.

Types of mist eliminator:

1. Wire mesh mist eliminators:

Demisters can reduce the residence time required to separate a given liquid droplet size by reducing the volume and associated cost of separator equipment. Demisters are often used where vapor quality is important in regard to entrained liquids, particularly where separator equipment costs are high (e.g., high-pressure systems) or where space or weight savings are advantageous.